|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Robotics & Automation | >Step-by-step guide to robot issues |

Step-by-step guide to robot issues

07 February 2019

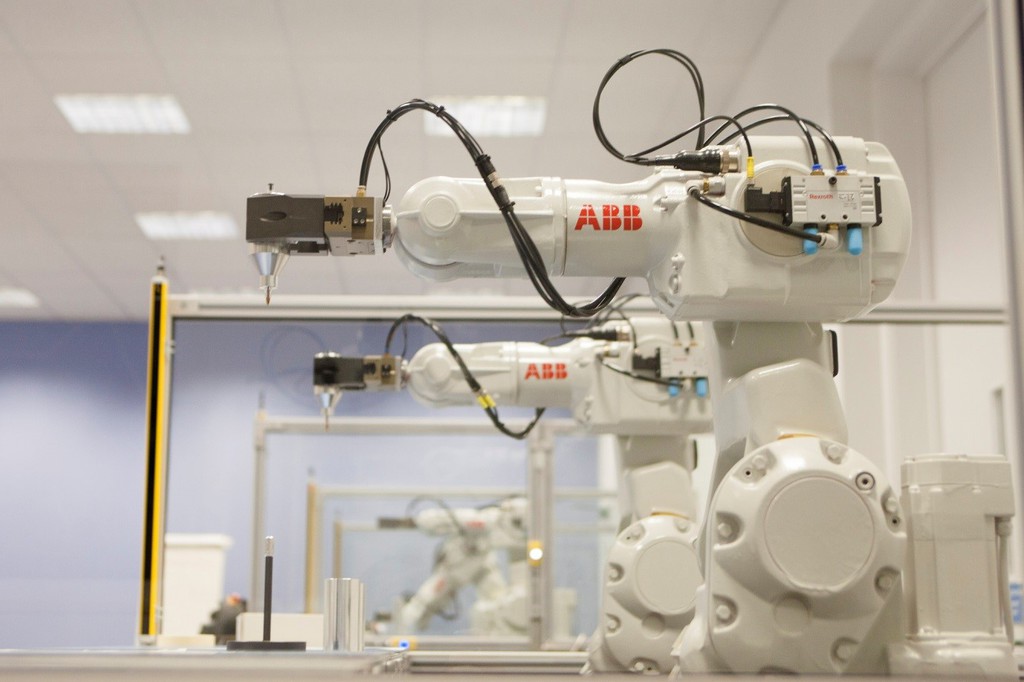

At its recent Switch to Robots seminar, ABB demonstrated how robots can help UK SME manufacturing companies become more productive and competitive.

The seminar provided a step-by-step guide to key issues around specifying, installing and operating a robot, including how to assess which processes can be automated and how to develop the right solution for your needs.

Other topics covered included how to calculate the potential return on investment that can be achieved in different types of applications and how to make the case for an investment to a financial director.

A hands-on workshop session in ABB’s training centre provided the opportunity to see and use some of the latest robot technology, including ABB’s RobotStudio offline programming software, which helps to reduce the time and cost of setting up a robot system by enabling robot cells to be modelled and tested off-line.

“UK manufacturers are struggling to keep pace with other leading nations that are able to quickly produce high-quality goods at low costs. For UK SMEs to remain competitive they must embrace digital technologies to increase their productivity,” says Mike Wilson, general industry sales manager for ABB Robotics in the UK and Ireland. “Our Switch to Robots event was designed to help businesses to easily identify whether a robot could be beneficial and explained the steps they need to take in specifying and installing the best solution for their requirements.”

- ABB's robot training masterclasses now available online

- Robot demonstration cell

- ABB’s largest ever robot '25% faster than the competition'

- Robotic automation: Survey highlights areas of concern

- ABB launches next generation cobots

- First UK order for YuMi

- Seminar to explain robot automation benefits to SMEs

- Robots: Swappage scheme

- Demonstrating the power of robotic intralogistics solutions

- Software turning robotic opportunities into reality

- Latest robots: Slim and easy to install

- APP that controls robots

- Collaborative robots: Risks and rewards

- Precision bearings aid smart grasping

- Collaborative robots: Safety matters

- 3D simulation program for robot control

- Bearings chosen for robotic exoskeletons

- Cobot collaboration delivers entry-level vision-guidance

- Robots boost profitability for machining company

- Entry-level vision-guided cobot system